OEM concepts and medical products – Our customized solutions

Are you faced with a special challenge that requires a custom product solution? We got the solution! With the OEM concept, we have been meeting the specific and individual needs of your company. Discover more and explore our OEM medical products.

Home • OEM

OEM medical equipment –

All around the world

In addition to our Gimmi® brand, we have been supplying OEM solutions for the past 30 years. These models have gained immense popularity not only in Germany but also internationally, with our most dedicated customers: In the USA, China, Japan and across Europe.

The OEM solution –

customized solutions

Gimmi specializes in OEM solutions and tailors them to your needs. We offer you customized end products as well as expert advice. Your medical product not only reflects the quality and precision associated with Gimmi, but also bears your company’s name.

Distributed by –

your company´s name

This model allows you to market an already approved medical device under your own name. The OEM products are labeled with your company name and the words “Distributed by”. Our service offers the comprehensive support that this dynamic market demands.

OEM Process –

turning Ideas into Reality

When you request a product, we initiate the whole process. We determine which supplier is best suited to bring the project to life. For different product groups i.e. scissors and/or needle holders, various manufacturers are considered.

7-step development process for your OEM medical product

1

Product idea / request according to SOW

You as the customer provide a “Statement of Work” (SOW) outlining your requirements to Gimmi.

2

Feasibility

After receiving the SOW, we evaluate its technical feasibility and whether the selected manufacturer can meet the request.

3

Regulatory evaluation

Ensuring adherence to regulatory standards for seamless product integration.

4

Risk Analysis

We analyze the general risk of the product in accordance with the applicable regulations and standards.

5

Prototyping

The selected supplier then comes up with a prototype. From there, the process continues with the customer. You may request changes or additional prototypes. Only when you are completely convinced of the result, the prototype is finalized.

6

Benchmarking

Benchmarking is performed to ensure the product meets the necessary standards.

7

Customer confirmation / serial production

Once the prototype is finalized, it moves into serial production with the customer.

It’s important to note that the customer is responsible for the entire registration and technical documentation. This is because the devices bear the customer’s logo rather than Gimmi’s. Nevertheless, we help throughout the whole process.

Extensive Supplier Network – Together we create OEM medical products

Gimmi boasts a vast network of suppliers, comprising 15 dedicated OEM partner companies and over 400 specialized medical technology companies and manufacturer. This network empowers us to create custom made medical products and to handle small production quantities. Together, we ensure the highest quality products and special surgical instruments can proudly bear the “Made in Germany” mark, since most of our partners are primarily concentrated around Tuttlingen. This also provides several advantages, including:

- Short distances

- Speedier collaborations

- Eco-friendliness

- Enhanced efficiency

Extensive Supplier Network – Together we create OEM medical products

Gimmi boasts a vast network of suppliers, comprising 15 dedicated OEM partner companies and over 400 specialized medical technology companies and manufacturer. This network empowers us to create custom made medical products and to handle small production quantities. Together, we ensure the highest quality products and special surgical instruments can proudly bear the “Made in Germany” mark, since most of our partners are primarily concentrated around Tuttlingen. This also provides several advantages, including:

- Short distances

- Speedier collaborations

- Eco-friendliness

- Enhanced efficiency

OEM products in various medical fields

OEM medical devices find applications across various medical specialties and are used like every other medical device with the aim of realizing the perfect outcome for patients. Two highly sought-after areas in the field of medical technology are for example:

Robotics –

in medical technology

Robotics is advancing healthcare rapidly, with hybrid systems leading the way. These systems enable surgeries to be performed remotely, bridging geographical gaps between patients and surgeons. They significantly reduce patient trauma by minimizing skin damage and decreasing the risk of accidents, as robots work with remarkable precision. This innovation is particularly important for further developments in the robotics field.

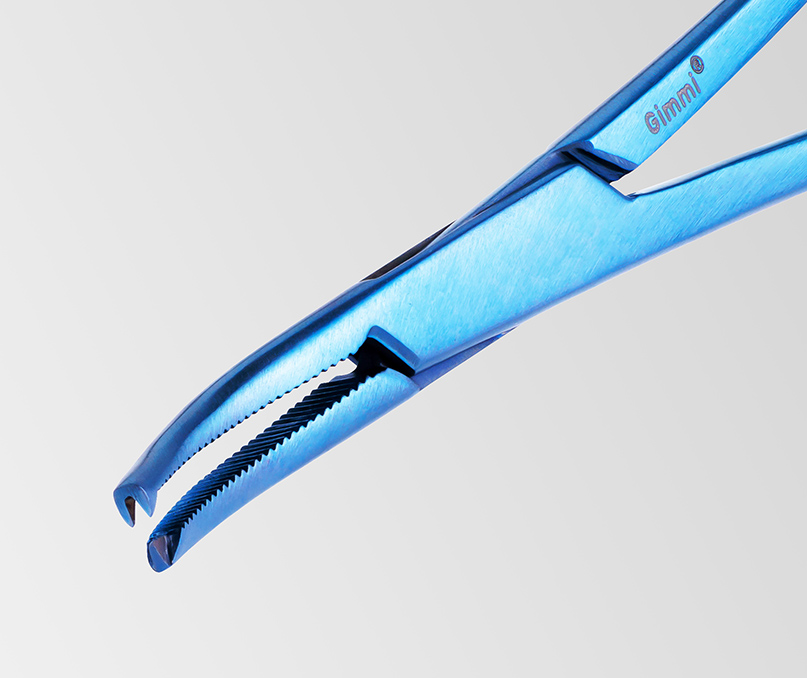

Open surgery –

with stainless steel and titanium instruments

Open surgery, including the use of i.e., needle holders, scissors, and other instruments made of stainless steel or titanium, are vital to various medical procedures and hold a prominent place in the industry. These instruments are known for their durability and reliability. They are important in ensuring that medical treatments are performed successfully and with precision. These factors make them an important part of the medical industry.

Benefits of OEM medical devices

The utilization of OEM medical products offers several notable advantages for healthcare providers, patients, and healthcare system.

Customization and branding with OEM

OEM medical devices empower healthcare companies with the flexibility to customize equipment, aligning seamlessly with their brand identity and specific requirements. This flexibility ensures that the devices meet the unique needs, fostering a sense of transparency and reliability.

Quality assurance and compliance with OEM

By partnering with reputable OEM manufacturers, healthcare companies gain access to quality-assured devices that comply with stringent regulatory standards. These devices undergo rigorous testing and quality control measures to ensure optimal performance and patient safety.

Cost-effectiveness of OEM

Collaborating with OEM manufacturers to elaborate medical equipment can often lead to cost savings for healthcare companies. By leveraging the expertise and infrastructure of OEM manufacturers, you can streamline your supply chain, reduce overhead costs, and allocate resources more efficiently.

Technological advancements: OEM creates innovation

OEM medical products are at the forefront of innovation in the healthcare industry. By partnering with OEM manufacturers, healthcare companies gain access to cutting-edge technologies and advancements, enabling them to deliver state-of-the-art care to their patients.

Contact us

For more information, please contact our OEM manager, Mr. Robin Fox, using the form below.